Case Studies

How we helped others improve their internal processes

INDUSTRIAL CONTROL SYSTEMS

-

Comprehensive Automation Solutions: Revolutionizing Business Efficiency

At Integrated Control Systems, Inc., our primary focus is collaborating with clients to create innovative systems and enhance current ones. This strategy seeks to address the evolving needs of manufacturing, enhance quality and safety benchmarks, reduce operator strain, and increase productivity by decreasing waste.

In today’s fast-paced world, businesses are under constant pressure to maximize efficiency, reduce costs, and deliver faster results. One of the key ways to achieve these objectives is through automation. Comprehensive automation solutions are transforming industries, allowing companies to streamline processes, eliminate human error, and scale operations. But what exactly are these solutions, and how can they benefit your business? Let’s explore.

What are Comprehensive Automation Solutions?

Comprehensive automation solutions refer to a suite of technologies, tools, and systems that work together to automate repetitive tasks, workflows, and processes across various business functions. These solutions often integrate advanced technologies such as robotic process automation (RPA), artificial intelligence (AI), and machine learning (ML) to provide a more dynamic and adaptable automation framework.

Instead of focusing solely on a single task, comprehensive solutions adopt a holistic approach that encompasses various functions, including customer service, human resources, supply chain management, and IT operations. This all-encompassing automation has the potential to significantly enhance an organization’s overall productivity and performance.

Key Components of Automation Solutions

- Robotic Process Automation (RPA)

RPA allows businesses to automate rule-based, repetitive tasks traditionally performed by humans. These tasks can include anything from data entry to invoice processing and even handling customer queries. RPA robots work faster than humans, eliminate errors, and operate 24/7, freeing up human employees for more strategic work. - Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML introduce cognitive capabilities into automation. They enable systems to analyze data, learn from patterns, and make decisions without human intervention. These technologies are especially useful for processes that require adaptability and continuous improvement, such as customer service chatbots, predictive maintenance, and fraud detection. - Workflow Automation

Workflow automation tools help organizations create, manage, and optimize business processes by defining rules and steps for each process. For example, automating the approval workflow for a purchase order can save time, reduce delays, and ensure compliance with internal policies. - IT Process Automation (ITPA)

IT process automation helps IT departments improve service delivery, reduce downtime, and manage tasks like system monitoring, software updates, and network management. It allows for more efficient and secure IT infrastructure management, minimizing the need for human intervention. - Integration Platforms

Comprehensive automation solutions often require integrating disparate systems, from CRMs and ERPs to HR platforms and customer-facing applications. Integration platforms ensure that these systems work together seamlessly, enabling end-to-end process automation.

Benefits of Implementing Comprehensive Automation

- Increased Efficiency and Productivity

Automation accelerates processes, reduces bottlenecks, and ensures tasks are completed consistently and accurately. By eliminating repetitive tasks, employees can focus on more value-driven activities such as innovation, strategy, and customer engagement. - Cost Savings

Automating labor-intensive processes leads to significant cost savings. Whether it’s reducing the number of employees required to perform manual tasks or cutting down on operational errors, businesses can see a tangible improvement in their bottom line. - Error Reduction and Compliance

Human errors in tasks such as data entry or compliance reporting can have costly consequences. Automation ensures that these processes are executed flawlessly and consistently, thus improving accuracy and ensuring compliance with regulatory standards. - Scalability

As businesses grow, manual processes become unsustainable. Automation provides scalability, allowing companies to increase output without a corresponding increase in resources. Automated systems can easily handle larger volumes of work, whether it’s processing customer orders or managing IT infrastructure. - Better Decision Making

With AI and ML, automation can provide valuable insights by analyzing data and identifying trends that might not be visible to human eyes. Businesses can use these insights to make informed decisions, improve customer experiences, and predict future trends. - Employee Satisfaction

Automation eliminates mundane and repetitive tasks, allowing employees to focus on more engaging and intellectually stimulating work. This not only improves job satisfaction but also enhances overall morale and productivity within the organization.

Use Cases Across Industries

- Manufacturing

Automation solutions in manufacturing are not new, but comprehensive solutions take things to the next level. From robotic arms assembling products to AI-powered predictive maintenance that ensures machinery doesn’t break down, automation can revolutionize production efficiency and minimize downtime. - Healthcare

In the healthcare sector, automation is helping with everything from patient scheduling and electronic health record (EHR) management to more complex processes like AI-driven diagnostics and robot-assisted surgeries. These solutions can improve patient outcomes, reduce human errors, and save time for healthcare professionals. - Finance and Banking

Automation in finance is revolutionizing processes like loan processing, fraud detection, KYC (Know Your Customer) verification, and transaction monitoring. By automating these complex workflows, financial institutions can improve accuracy, ensure compliance, and offer a better customer experience. - Retail and E-commerce

Retailers are using automation for inventory management, personalized marketing, and customer service. Chatbots, AI-driven recommendations, and automated supply chain solutions help retailers stay competitive in a fast-paced market while improving operational efficiency. - Human Resources

HR departments are increasingly leveraging automation to streamline tasks such as recruitment, onboarding, payroll management, and performance evaluations. By automating these processes, HR teams can focus on improving employee engagement and strategic workforce planning.

Challenges in Automation

While automation offers numerous benefits, businesses must address several challenges:

- Integration Complexity: Automating end-to-end processes often involves integrating multiple legacy systems. This can be complicated and require significant technical expertise.

- Security Risks: Automating processes that handle sensitive data, such as financial transactions or customer information, raises concerns about security. Businesses must invest in robust cybersecurity measures to mitigate risks.

- Change Management: Shifting to automated systems can cause resistance from employees who fear job loss or uncertainty. Effective change management strategies and employee training are crucial for successful implementation.

Conclusion

Comprehensive automation solutions are no longer a luxury; they are essential for businesses seeking to remain competitive in today’s dynamic marketplace. By automating processes across various departments, organizations can boost efficiency, reduce costs, and deliver better outcomes for customers and employees alike. As technology continues to evolve, the potential for automation is limitless, paving the way for smarter, more agile businesses.

Whether you’re just beginning your automation journey or looking to optimize existing processes, embracing comprehensive automation solutions can be the game-changer your business needs to thrive in the modern world.

This is what we focus on here at Integrated Control Systems, Inc. Working with our clients to develop new systems and upgrading existing ones to address evolving markets, improve quality and safety, reduce operator stress, and enhance productivity through the reduction of waste.

For more information: https://integrated-controls.com/contact-us/

- Robotic Process Automation (RPA)

-

Assembly Automation: Transforming Manufacturing for the Future

In the fast-evolving world of manufacturing, businesses are constantly seeking ways to streamline production processes, improve efficiency, and reduce costs. One of the most significant advancements in recent years is assembly automation. This technology, which integrates robotics, artificial intelligence (AI), machine learning, and advanced sensors, is reshaping how companies assemble products, from electronics to automotive parts.

In this blog, we’ll explore the concept of assembly automation, its benefits, key components, challenges, and its impact on various industries.

What is Assembly Automation?

Assembly automation refers to the use of automated systems—such as robotic arms, conveyors, vision systems, and AI-driven software—to perform tasks that were once carried out by human workers. These tasks include assembling parts, inspecting products, packaging, and performing quality checks. The goal is to speed up the manufacturing process, enhance product quality, and reduce human error.

Traditionally, assembly lines relied heavily on manual labor to fit parts together and complete products. With the advent of automation, robots can now handle repetitive and intricate tasks with greater precision, speed, and consistency. This has led to a significant transformation in industries ranging from consumer electronics to automotive manufacturing.

Key Benefits of Assembly Automation

- Increased Efficiency: Automated systems work much faster than human labor, particularly when it comes to repetitive tasks. Robots do not require breaks, they don’t tire, and they can work around the clock. As a result, assembly lines become more productive, and manufacturing capacity increases without the need for additional human resources.

- Improved Product Quality: One of the most notable advantages of automation is its ability to produce high-quality, consistent products. Robots follow precise instructions and work with extreme accuracy, reducing the likelihood of defects that often occur due to human error. This ensures that each product meets stringent quality standards, reducing waste and the need for costly rework.

- Cost Savings: While the initial investment in automation technology can be substantial, the long-term savings are significant. Automated systems reduce labor costs, minimize material waste, and enhance product consistency. With fewer errors and less need for manual intervention, the overall production cost per unit can decrease over time.

- Improved Worker Safety: Assembly lines often involve tasks that pose risks to human workers, such as lifting heavy objects or working with dangerous machinery. Automation can reduce the number of manual laborers required on the floor, allowing them to focus on more complex and creative tasks while robots handle the physically demanding and hazardous aspects of assembly.

- Flexibility and Scalability:Modern assembly automation systems are highly adaptable. Whether it’s switching from one product design to another or adjusting production volumes in response to market demand, automated systems can be reprogrammed and reconfigured quickly. This flexibility is especially beneficial for businesses that need to respond to changing market trends or customer preferences.

Key Components of Assembly Automation

- Robotic Arms: Robotic arms are among the most visible components of assembly automation. These arms can perform tasks such as welding, screwing, picking, placing, and sorting. With advancements in AI, these robots are becoming more intelligent and capable of handling complex tasks that require precision.

- Conveyor Systems: Conveyor belts play an essential role in assembly automation by moving products through various stages of the production process. These systems can be integrated with other technologies, such as robotic arms or vision systems, to optimize the flow of materials and ensure smooth operations.

- Vision Systems: Machine vision systems use cameras and sensors to inspect products at various stages of the assembly process. These systems can detect defects, measure dimensions, and ensure that products meet quality standards. They are also used in picking and sorting tasks, where they guide robotic arms in handling specific components.

- AI and Machine Learning: Artificial intelligence (AI) and machine learning (ML) are increasingly being integrated into automated assembly lines. These technologies enable systems to “learn” from data, optimize processes, predict maintenance needs, and adjust operations in real-time for maximum efficiency.

- Collaborative Robots (Cobots): Collaborative robots, or cobots, are designed to work alongside human operators safely. These robots handle tasks such as part assembly, inspection, or material handling, while humans focus on more complex or delicate tasks. Cobots are smaller, flexible, and can easily be integrated into existing workstations, enhancing productivity without requiring major infrastructure changes.

Industries Benefiting from Assembly Automation

- Automotive Industry: The automotive industry has long been a leader in adopting assembly automation. Robots have revolutionized the way car parts are assembled, from installing engines to welding frames. Automation has allowed manufacturers to produce vehicles faster, more efficiently, and with higher levels of precision. Additionally, automation has made it possible for manufacturers to meet the growing demand for electric vehicles and autonomous cars by enabling scalable and adaptable production lines.

- Electronics Manufacturing: In the electronics sector, assembly automation is critical for producing devices such as smartphones, laptops, and televisions. Automated systems help assemble small, delicate components, such as microchips and circuit boards, with high precision. The ability to assemble products quickly and accurately has allowed electronics manufacturers to keep up with the fast pace of technological advancement.

- Consumer Goods:From appliances to toys, the consumer goods industry has greatly benefited from assembly automation. Robots are used for assembly, packaging, and quality control, ensuring that products are made to exact specifications and delivered to consumers faster. Automation has also helped consumer goods companies scale production and reduce costs.

- Pharmaceuticals and Medical Devices:In the pharmaceutical and medical device industries, assembly automation helps maintain the strict quality and safety standards required. Automated systems handle everything from assembling drug packaging to manufacturing medical devices. This ensures both compliance and reliability while reducing the risk of contamination or human error.

Challenges of Assembly Automation

While the benefits of assembly automation are clear, there are several challenges to consider:

- High Initial Investment: The upfront costs of implementing automated systems can be high. This includes purchasing robotics, integrating software, and training staff to operate and maintain the systems. Smaller companies, in particular, may find it difficult to justify such an investment.

- Technical Complexity: Automating an assembly line requires technical expertise to set up, integrate, and maintain the systems. Companies need skilled workers who understand robotics, AI, and automation technology, which may require extensive training or hiring new talent.

- Job Displacement: While automation creates new jobs in areas like programming and robotics maintenance, it can also lead to job displacement for workers involved in manual assembly tasks. It’s important for companies to consider the social and economic impacts of automation and invest in retraining programs to help employees transition to new roles.

- Cybersecurity Concerns:As assembly lines become more interconnected through AI and IoT (Internet of Things) devices, they are also more vulnerable to cyberattacks. Protecting sensitive data and ensuring the security of automated systems is crucial for avoiding disruptions in production.

Conclusion

Assembly automation is transforming the manufacturing landscape by increasing efficiency, improving product quality, and enabling scalability. As technology continues to advance, the future of manufacturing looks increasingly automated, with companies embracing robots, AI, and machine learning to stay competitive in a rapidly changing market.

While challenges exist—particularly in terms of cost, complexity, and workforce impact—the benefits far outweigh the potential drawbacks. By carefully considering the integration of automated systems, businesses can create more sustainable, efficient, and innovative production processes that meet the demands of the modern world.

Embracing assembly automation is no longer just an option; it’s a necessity for staying relevant in the future of manufacturing.

This is what we focus on here at Integrated Control Systems, Inc. Working with our clients to develop new systems and upgrading existing ones to address evolving markets, improve quality and safety, reduce operator stress, and enhance productivity while reducing waste.

For more information: https://integrated-controls.com/contact-us/

-

Understanding Industrial Controls: The Backbone of Modern Automation

In today’s rapidly evolving industrial landscape, the role of industrial controls has never been more crucial. These systems ensure the efficient operation of machinery and processes across various sectors, from manufacturing to energy production. In this blog, we’ll explore what industrial controls are, their components, types, and the future trends shaping this essential field.

What Are Industrial Controls?

Industrial controls are systems and devices used to manage, command, direct, or regulate the behavior of other devices or systems. Essentially, they enable the automation of processes, enhancing efficiency, safety, and reliability in industrial operations. These controls can range from simple mechanical devices to complex computer-based electro-mechanical systems.

Key Components of Industrial Control Systems

- Sensors: These devices collect data from the environment, such as temperature, pressure, and flow rates. Sensors are crucial for providing real-time information that drives decision-making.

- Controllers: Often the brain of the control system, controllers process sensor data and execute commands. They can be programmable logic controllers (PLCs), distributed control systems (DCS), or more advanced solutions like industrial PCs.

- Actuators: These devices carry out the commands from the controllers, affecting physical changes in the system, such as opening a valve or adjusting a motor’s speed.

- Human-Machine Interfaces (HMIs): HMIs allow operators to interact with the control system, providing visual feedback, data analysis, and manual control options. A well-designed HMI enhances user experience and operational efficiency.

- Communication Networks: These enable different components of the control system to exchange data, often employing protocols such as Ethernet, Modbus, or Profibus.

Types of Industrial Control Systems

- Programmable Logic Controllers (PLCs): Highly reliable and flexible, PLCs are widely used for discrete and continuous control tasks in various industries. They excel in handling complex logic operations and can easily be reprogrammed for different tasks.

- Distributed Control Systems (DCS): DCS are ideal for large, complex processes, typically found in industries like oil and gas or chemical production. They distribute control functions across multiple locations, enhancing redundancy and reliability.

- Supervisory Control and Data Acquisition (SCADA): SCADA systems monitor and control large-scale processes, often spread across vast geographical areas. They provide a high-level overview, allowing operators to manage and analyze data efficiently.

- Safety Instrumented Systems (SIS): Focused on ensuring safety in industrial environments, SIS protect processes from dangerous conditions by automatically executing safety measures when needed.

Benefits of Industrial Controls

- Increased Efficiency: Automation reduces manual intervention, leading to faster production times and lower operational costs.

- Improved Safety: By monitoring critical parameters and implementing safety protocols, industrial controls minimize the risk of accidents.

- Enhanced Data Collection: Real-time data allows for better decision-making and predictive maintenance, reducing downtime and maintenance costs.

- Quality Assurance: Consistent monitoring and control help maintain product quality and adherence to standards.

Future Trends in Industrial Controls

As technology continues to advance, the field of industrial controls is set to evolve significantly:

- Industrial Internet of Things (IIoT): The integration of IoT devices into industrial controls will facilitate smarter, more interconnected systems, enhancing data collection and analysis.

- Artificial Intelligence and Machine Learning: AI can optimize control processes by analyzing large datasets to identify patterns and predict outcomes, leading to more efficient operations.

- Cybersecurity: As industrial control systems become more connected, protecting them from cyber threats will be paramount. Enhanced security measures will be critical to safeguarding operations.

- Edge Computing: By processing data closer to the source, edge computing can reduce latency and improve the efficiency of industrial control systems.

Conclusion

Industrial controls are fundamental to the smooth operation of modern industries. By understanding their components, types, and future trends, businesses can better leverage these systems to enhance efficiency, safety, and productivity. As we move forward, embracing new technologies and innovations in industrial controls will be essential for staying competitive in an increasingly automated world. Whether you’re a seasoned professional or just starting in the field, keeping abreast of these developments will undoubtedly pay off in the long run.

This is what we focus on here at Integrated Control Systems, Inc. Working with our clients to develop new systems and upgrading existing ones to address evolving markets, improve quality and safety, reduce operator stress, and enhance productivity through the reduction of waste.

For more information: https://integrated-controls.com/contact-us/

-

For a testimonial from our client CLICK HERE.

THE CHALLENGE

The customer’s cap machines had both obsolete and proprietary controls, thus when the cap machines broke down, there were no vendors to repair or replace them.

THE ANALYSIS

An analysis of their process indicated the old controls for their cap machines needed to be upgraded so that they could buy off-the-shelf parts and get support from local suppliers providing savings, etc.

THE SOLUTION AND RESULT

ICSI re-engineered the controls for their cap machines. We replaced the obsolete and proprietary controls with better, modern devices that can be bought off the shelf. These changes enabled the company to keep these machines in production, with a significant reduction in scrap.

ROBOTIC ASSEMBLY POKA-YOKE CELLS

-

Vision Inspection Systems: Revolutionizing Quality Control in Manufacturing

In today’s fast-paced manufacturing environment, ensuring product quality is paramount. As production lines grow increasingly complex, traditional inspection methods often fall short. Enter vision inspection systems—advanced technological solutions that leverage cameras and artificial intelligence to enhance quality control. In this blog, we’ll explore what vision inspection systems are, how they work, their benefits, and future trends in this exciting field.

What Are Vision Inspection Systems?

Vision inspection systems are automated tools that use camera technology and software algorithms to inspect products on the manufacturing line. These systems can identify defects, measure dimensions, verify assembly, and ensure that products meet quality standards. By integrating these systems into production processes, manufacturers can achieve higher levels of accuracy and efficiency.

Key Components of Vision Inspection Systems

- Cameras: High-resolution cameras are the eyes of the inspection system. They capture images of products at various stages of the manufacturing process.

- Lighting: Proper lighting is crucial for accurate image capture. Different types of lighting, such as LED or backlighting, are used to enhance the visibility of features being inspected.

- Software Algorithms: Advanced software processes the images captured by the cameras. This may include pattern recognition, edge detection, and machine learning techniques to identify defects or deviations from specifications.

- User Interface: A user-friendly interface allows operators to monitor inspections, review results, and adjust parameters as needed.

- Integration Capabilities: Vision systems can often be integrated with other manufacturing systems, such as SCADA or ERP systems, for seamless data flow and analysis.

Benefits of Vision Inspection Systems

- Enhanced Accuracy: Vision systems can detect even the smallest defects that human inspectors might miss, significantly improving product quality.

- Increased Efficiency: Automating the inspection process reduces the time needed for quality control, allowing for faster production cycles and minimizing downtime.

- Consistency: Unlike human inspectors, vision systems provide consistent results, ensuring that every product is evaluated with the same level of scrutiny.

- Real-Time Feedback: Many vision systems offer real-time data analysis, allowing for immediate corrective actions if defects are detected, thus preventing faulty products from reaching customers.

- Cost Savings: While the initial investment in vision inspection technology can be significant, the long-term savings from reduced waste, rework, and improved quality often justify the cost.

Applications of Vision Inspection Systems

- Electronics Manufacturing: In the production of circuit boards and electronic components, vision systems are used to verify solder joints, component placement, and surface defects.

- Food and Beverage Industry: These systems ensure that packaging is sealed correctly, labels are applied accurately, and that products meet safety standards.

- Automotive Industry: Vision inspection systems are employed to check for proper assembly, alignment, and surface finish on components and final products.

- Pharmaceuticals: In drug manufacturing, these systems are critical for verifying labels, ensuring correct dosage, and checking packaging integrity.

- Textiles and Apparel: Vision systems can inspect fabric quality, stitching, and color consistency in textile manufacturing.

Future Trends in Vision Inspection Systems

- Artificial Intelligence and Machine Learning: As AI technology evolves, vision systems will become even more sophisticated, learning from data to improve defect detection and decision-making processes.

- 3D Vision Systems: The development of 3D imaging technology will enhance the ability to inspect complex shapes and assemblies, providing more accurate assessments of products.

- Edge Computing: Integrating edge computing will allow for faster processing of images directly at the source, reducing latency and improving real-time decision-making.

- Increased Connectivity: As Industry 4.0 continues to shape manufacturing, vision inspection systems will become more interconnected, allowing for seamless data exchange across the production line.

- Mobile and Remote Monitoring: Advances in mobile technology will enable operators to monitor inspection results and system performance remotely, facilitating quicker response times and greater flexibility.

Conclusion

Vision inspection systems are transforming the landscape of quality control in manufacturing. By leveraging advanced imaging technology and artificial intelligence, these systems provide manufacturers with the tools needed to enhance product quality, increase efficiency, and reduce costs. As technology continues to evolve, the future of vision inspection systems promises even greater capabilities and integration, making them an essential component of modern manufacturing processes. Whether you’re in electronics, automotive, food production, or any other sector, investing in vision inspection technology can significantly enhance your quality assurance efforts and ultimately drive business success.

This is what we focus on here at Integrated Control Systems, Inc. Working with our clients to develop new systems and upgrading existing ones to address evolving markets, improve quality and safety, reduce operator stress, and enhance productivity while reducing waste.

For more information: https://integrated-controls.com/contact-us/

-

The Future of Manufacturing: Robotic Assembly in Modern Industry

As industries strive for efficiency and precision, robotic assembly has emerged as a game-changer in manufacturing processes. From automotive production lines to electronics assembly, robotics are transforming how products are built. In this blog, we’ll explore the fundamentals of robotic assembly, its benefits, challenges, and the future trends shaping this exciting field.

What is Robotic Assembly?

Robotic assembly refers to the use of robots to perform assembly tasks in manufacturing processes. These robots are programmed to handle various functions, such as picking and placing components, fastening parts, and quality inspection. Unlike traditional manual assembly, robotic systems can work tirelessly, with a high degree of accuracy and speed.

Key Components of Robotic Assembly Systems

- Robots: The backbone of any robotic assembly system, these can be articulated arms, collaborative robots (cobots), or specialized robots designed for specific tasks.

- End Effectors: These are tools attached to the robot’s arm that perform the actual assembly tasks. They can include grippers, screwdrivers, or welding torches, depending on the application.

- Vision Systems: Many robotic assembly systems utilize cameras and sensors to guide the robots. Vision systems help identify components, ensure correct placement, and perform quality checks.

- Control Systems: These manage the operation of the robots, including movement, task execution, and communication with other machines in the assembly line.

- Software: Programming and software tools are essential for designing, simulating, and monitoring robotic assembly processes.

Benefits of Robotic Assembly

- Increased Efficiency: Robots can operate continuously without breaks, significantly increasing production rates and reducing cycle times.

- Enhanced Precision: With advanced sensors and control systems, robotic assembly provides unparalleled accuracy, minimizing errors and waste.

- Cost Savings: Although the initial investment may be high, robotic assembly can lead to lower labor costs and reduced operational expenses over time.

- Improved Safety: Robots can handle hazardous materials and perform repetitive tasks, reducing the risk of injury to human workers.

- Flexibility: Modern robotic systems can be reprogrammed for different tasks, allowing manufacturers to quickly adapt to changing product lines or market demands.

Challenges in Robotic Assembly

- High Initial Costs: The investment required for robotic systems can be substantial, which may deter some companies, especially smaller manufacturers.

- Complex Integration: Incorporating robotics into existing manufacturing processes can be challenging, requiring careful planning and integration of various systems.

- Skills Gap: There is a growing demand for skilled workers who can program, maintain, and troubleshoot robotic systems, which can be a barrier to widespread adoption.

- Limited Flexibility in Some Applications: While robots excel in repetitive tasks, they may struggle with intricate assembly operations that require dexterity or adaptability.

Future Trends in Robotic Assembly

- Collaborative Robots (Cobots): These robots are designed to work alongside human operators, enhancing flexibility and safety in assembly tasks. Cobots are often easier to program and can adapt to various applications.

- Artificial Intelligence and Machine Learning: Integrating AI can enhance robotic systems, allowing them to learn from their environments and improve their performance over time.

- Advanced Vision Systems: Enhanced vision technology will improve robots’ ability to identify and manipulate components, leading to better quality control and increased adaptability.

- Remote Monitoring and Maintenance: IoT and cloud technologies will enable manufacturers to monitor robotic systems remotely, allowing for predictive maintenance and reduced downtime.

- Sustainable Manufacturing: As companies focus on sustainability, robotic assembly systems will be developed to minimize waste and energy consumption, aligning with eco-friendly practices.

Conclusion

Robotic assembly is revolutionizing the manufacturing landscape, offering numerous advantages in efficiency, precision, and safety. While challenges remain, advancements in technology and a growing understanding of robotics are paving the way for wider adoption across industries. As we look to the future, embracing robotic assembly will be essential for companies aiming to remain competitive in an increasingly automated world. Whether you’re a manufacturer or simply curious about the future of production, understanding robotic assembly is crucial in navigating this exciting frontier.

This is what we focus on here at Integrated Control Systems, Inc. Working with our clients to develop new systems and upgrading existing ones to address evolving markets, improve quality and safety, reduce operator stress, and enhance productivity while reducing waste.

For more information: https://integrated-controls.com/contact-us/

-

THE CHALLENGE

Customer, a tier 1 automotive supplier, required a dynamic visual inspection system to verify the presence of various components of a vehicle door, the system would communicate in tandem with another robot that would place the part in the station, and the system should be able to verify components based on the running part number.

THE ANALYSIS

An analysis of customer requirements indicated that due to the diversity of models to be executed, inspections to be carried out, and inspection tolerances, the application of a robotic system and a vision system would be adequate tools to ensure the confirmation of the assembly specifications.

THE SOLUTION

ICSi integrated an inspection cell composed of a compact high-speed 6-axis Yaskawa robot (GP7) and a Keyence vision system, as well as a simplified safety controller to ensure the operator’s safety, the robot is capable of selecting the model to inspect based on the bar code that the same vision system captures and is capable of reaching 9 different positions and a maximum of 32 vision inspections in less than 30 seconds, the HMI and PLC programming design allows adding, editing or deleting inspections without the need to make programming changes in the PLC and minimal changes in the robot program.

-

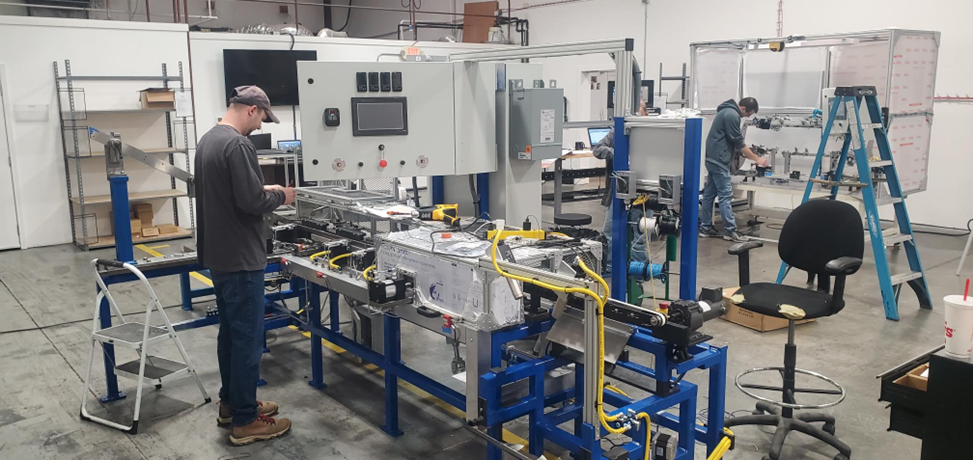

THE CHALLENGE

ICSI was commissioned to design and build a test train4ing assembly line for the company battery plant. This facility manufactures the lithium-ion batteries used in the company’s electric cars.

THE ANALYSIS

The system we designed called for trainers to be able to disconnect or interrupt selected circuits inside lockable junction boxes, and then have technicians trace down and pinpoint the problems.

THE SOLUTION

The completed system included three robots, two computerized camera inspection systems, and multiple sensors and safety systems set up for new technicians to train on.

THE RESULT

Now the company can safely and thoroughly train its battery assembly technicians offline. One of the most complicated test systems ICSI has completed, it has exceeded expectations and has positioned ICSi for more work with Nissan.

SCADA – Automated Quality Control

-

THE CHALLENGE

Due to the growing demand for variation unit-to-unit at one of the company’s automotive plants, ICSI was tasked with developing a quick and easy way to make modifications to the assembly process.

THE ANALYSIS

An analysis of the automotive tier 1’s automotive assembly process indicated an environment with the potential for operator error due to multiple variations of similar parts and the need for a flexible, user-friendly fail-proof traceability system.

THE SOLUTION

ICSI developed a user-customizable Parts Determining System (PDS) that utilizes bar code scanning, label printing, pick lights, torque readings, and screw counts to create a zero-error assembly and documentation system.

THE RESULT

The ICSI PDS helps manufacturers determine and verify the correct part when there are variations of similar parts used. It assists Engineering and Maintenance to make updates quickly and easily to reduce downtime. It also allows Quality Control to determine the real root cause when issues occur. For example: what part was picked, what was a given torque on a part, was the system in by-pass during an incident, etc.